APA’s solution

To design and carry out the robotization process, 5 robotic stations at a time at Shanghai General Motors.

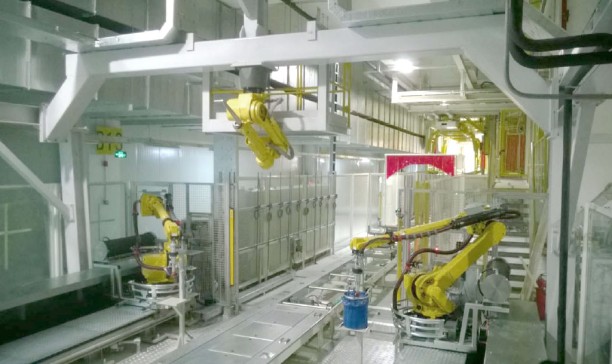

The first stations were created in Shenyang at the break of 2013/2014 followed by a copy of this factory in Wuhan. They included two stations for the UBS application and for Interior Sealing each, as well as one Rocker Panel station (threshold panel).

A single station included 2 to 6 FANUC robots. Control was divided between 2 PLC units: S7-319F master unit and a unit controlling Beckhoff material application.

Project components

- PLC Siemens 319F-3

- PLC Beckhoff and a Ethercat network

- Fanuc R30-ia robots

- PROFIBUS network

- ISRA and VIVA vision system

- SINGLE material temperature control units

- HMI – Intouch visualisation