Solution

The customer received a solution that met all the assumptions specified in the request for quotation. Two robots have been installed on the line: a belt conveyor that transports the panes inside the station, and a new turntable.

Main description

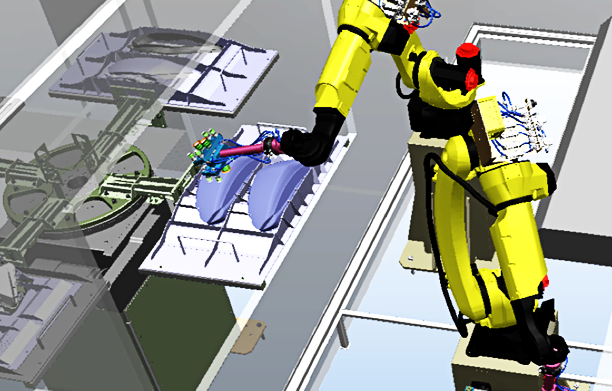

Operator mounts two panes on a pallet. These pallets are mounted on a belt conveyor. Operator, confirming the loading, starts the station's automatic cycle and the conveyor transports the lamps toward the robot. The robot first retrieves both lamps from the conveyor and puts them in dedicated places on the turntable. Lamps prepared in this way are transferred to the paint station. After the painting process, a second robot picks up the lamps and deposits them in an oven, where a several-minute heating process takes place. The finished product is picked up by the operator and packed into special containers.

Benefits

- Automation of the manual process,

- Acceleration of production,

Technologies used

- Series 1500 PLC,

- Two Fanuc robots,

- ITEM belt conveyor

- SEW Movitrac inverter,

- Euchner security gates,

- SICK curtains,

- Siemens TP900 Comfort operator panel,