APA Solution

Nazca 4.0 and Nazca BMS systems were implemented within the selected ABB robotic training room. Combined within a single platform, they provide:

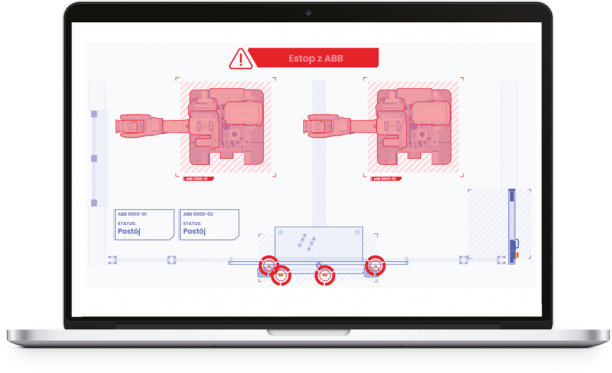

1. Easy access to data Ability to easily access current statistics, quality indicators or alarms from the training station. Data is available in the training room from the operator station, as well as computers and mobile devices of the training staff and trainees. For greater clarity, messages of all kinds are presented on the station's graphic overlay, making it easier to locate the source of the information.

2. Introduction to Predictive Maintenance

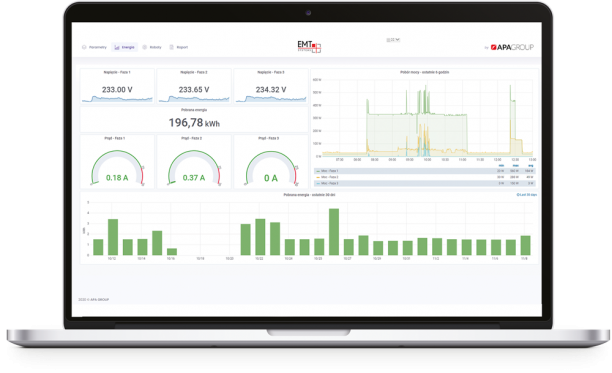

A method for preventing machine failures by analyzing machine parameters (e.g., current draw, temperature, operating speed, positioning) to identify patterns and predict problems before they occur. Analytics tools allow to monitor equipment health, optimize service intervals, and report irregularities in real time.

3. Monitoring of additional signals

Monitoring signals that are not used in the Industry 3.0 control process. After analysis of environmental conditions (temperature, humidity) or power supply parameters, their influence on the process is determined, allowing further optimization of the control cycle.

Main description

The project required the integration of both the existing infrastructure, i.e. ABB robots and Siemens S7-1200 PLC, as well as the extension of the functionality by collecting data from IIoT sensors and meters monitoring the work of the station.

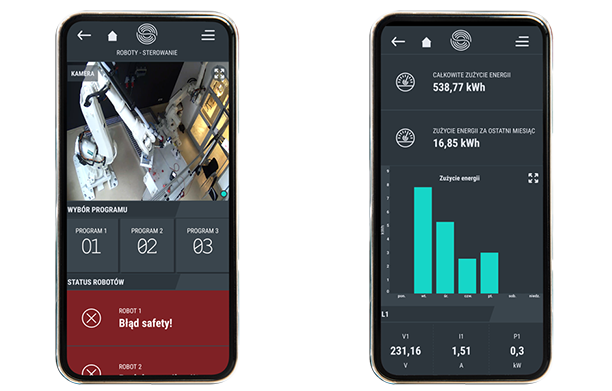

A mobile client application was provided for employees and trainees to install on their own phones. The application allows to monitor the parameters of the station, and during the course it is additionally possible to prepare a demo sequence of training robots. Thanks to the applied solution, students are prepared for the basics of Big Data analytics - they see what data can and should be monitored. At what frequency to archive and what amounts of information are collected during training.

The NAZCA system (4.0 + BMS) allows for the future connection of additional training rooms and thus the monitoring of a larger number of laboratories from the level of one software and, for example, the creation of comparative statements of energy consumption or the operating time of equipment during training.

.gif)

Benefits

The opportunity to present a qualitative technological change related to the implementation of the Industry 4.0 concept.

Curiosity

Combining Industry 4.0 and BMS solutions in a single platform provides even greater process and cost awareness. Want to learn more about this topic? Take part in the training!

Zastosowane technologie

- Performance monitoring of ABB robots

- Controlling the safety circuit of a robotic cell

- Verifying the energy efficiency of the programmed control trajectory

- Remote start-up of robots

- Video surveillance of a robotic cell

- Generating reports, voice notifications

- Support in analysing the causes of failures, downtime

- Lighting control

- Heating control

- Projector control

- Video surveillance

- Monitoring of electricity consumption and mains parameters