Solution

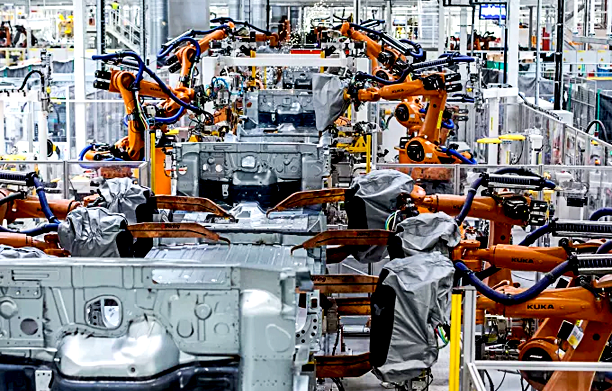

The customer received a solution that met all the assumptions specified in the request for quotation. Four robots were installed on the line along with an automatic sealing material feeding system.

Main description

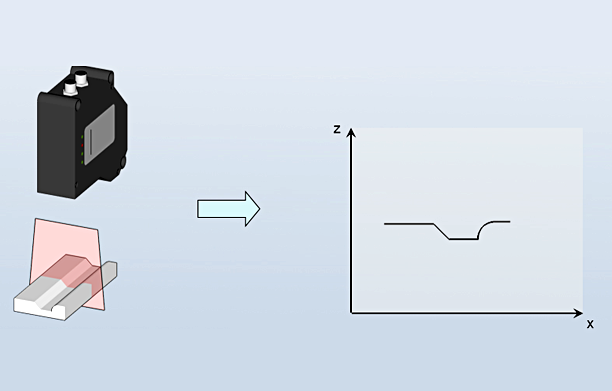

Information on the type of body being on the robotic station is retrieved from the RFID reading station. This type is sent to the PLC control system, which manages the operation of the robotic station. When the body reaches the base position and we know what type of body is currently at the station, the car is measured with the 3D system. The 3D cameras return XYZ correction, alignment of the body on the roller conveyor. XYZ offsets relative to the model are then sent to the robots. First, the robots perform the task of scanning the gap according to the XYZ body offset. Scanning and gap corrections are returned to the VMT system via BK LR300 sensors. Below is the result of scanning with such a sensor. Once the scanning is complete, the robots begin the work of applying the sealing material. The amount of injected sealing material depends on the width of the gap. The gap width is returned to the robot via the VMT system.

Benefits

- Automation of the manual process,

- Reduction in sealing material consumption,

- Ability to quickly increase production volume.

Technologies used

- PLC 319F-3PN/DP controller

- KUKA KR210 R3100 robots,

- Graco material feeding systems,

- Pepperl Fuchs vision systems (VMT),

- SICK scanners,