APA Solution

We coordinated the work of all our entities in a single platform – Nazca. The implemented solution streamlined the work of the warehouse and eliminated the chaos that appeared when a previously unannounced truck came to collect the goods.

Logistics is a dynamic environment full of variables. The huge number of factors and the large number of entities (including external ones) involved in the process makes the company dealing with the storage of goods constantly struggle with warehouse shortages, delays in the dispatch or receipt of products. Modern building and industrial space management systems can help in improving these processes. Within the Nazca framework, we coordinated elements of building automation, such as: CCTV system, fire safety system, alarms, energy analysis, air conditioning, heating and lighting – but also the extended external parking system and an ERP system already existing in the warehouse. Let’s take a look at how the logistics process took its shape after the introduction of automation and how it improved the loading of trucks.

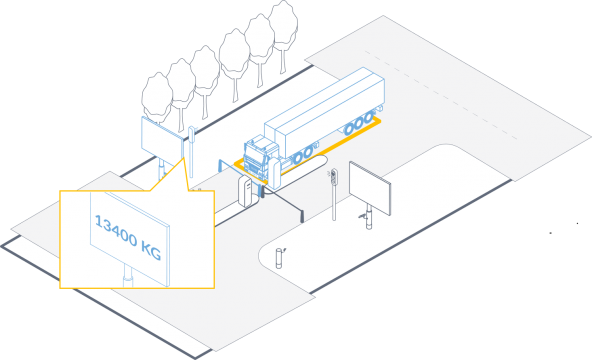

The activities started with the introduction of a vehicle notification system in the company and connecting it to the Nazca platform, responsible for processing the provided data. Each of the incoming drivers must now log on to the computer system and select a free loading window in the calendar panel, divided into 30-minute intervals. Entering the vehicle registration number and driver’s data makes it easier to identify the vehicle when it arrives at the entrance; Nazca scans the driver’s documents and verifies the vehicle registration numbers. Thanks to the solution, a vehicle which was not previously registered in the system will not enter the warehouse. What’s more, when entering the premises, the car is weighed and the driver is informed on a traffic light board of the hall or the ramp they are supposed to head to.

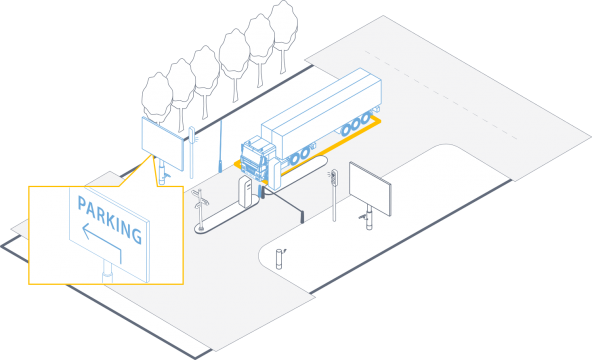

Delays and mistakes happen to the best of us. When a driver does not reach a certain time, the system directs them to a buffer car park, where they wait for the system to inform them via their mobile phone about the next free loading window in convenient conditions. Drivers also have access to a common waiting room, a hot beverage machine and an info kiosk, where they can check current loading information. In order not to miss their loading window again, the driver receives another SMS message requesting them to arrive at the entrance gate.

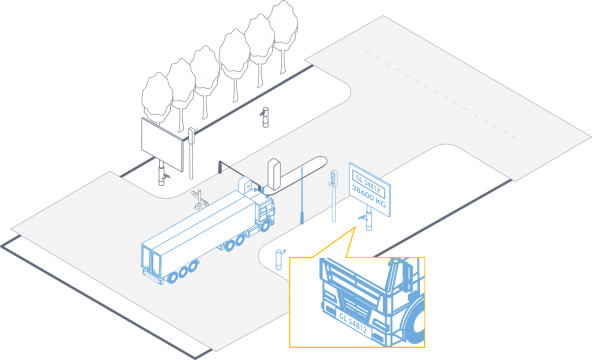

After the verification at the entrance, the driver is informed of the loading hall to which they should head. At the final location, Nazca verifies the vehicle’s license plates once again, and a CI document is issued during the loading. The vehicle is also weighed automatically. When leaving the warehouse, its weight is compared with the weight during loading. If there are no discrepancies, the driver can leave the premises; if not, they are stopped in order for them to provide explanations.

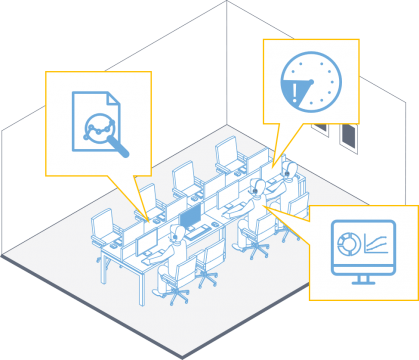

In addition to the automation of the loading process itself, the analytical possibilities offered by the connection to Nazca of other systems present in the warehouse should be noted. The data collected by the platform are stored in the Internet cloud, where by analysing them we can draw conclusions about periods of increased goods traffic or stagnation, consider additional warehouse stocking, or prepare for the need for additional employee service. Of course, the longer the system works in one place, the more useful information we can draw from it.

Benefits

- Easy access to key information – both by warehouse managers and external entities, e.g. drivers who come in or out (the system works on traditional computers, mobile and off-line).

- Less employees necessary for handling the warehouse – as was the case with this project. The creation of new warehouses did not result in the need to employ new warehouse workers.

- Better workflow in the warehouse and improved safety – this is mainly due to license plate scanning, vehicle weighing and Nazca connection to the monitoring and alarm system, as well as comprehensive management of the car park operation.

- Control over the entire process and possibility of anticipation of potential hazards.

- Relative simplicity of configuration of the platform, which – thanks to being based on popular construction automation norms and an open structure – allows for including a number of warehouse management systems in it.

- Easy access to key information – both by warehouse managers and external entities, e.g. drivers who come in or out (the system works on traditional computers, mobile and off-line).

- Less employees necessary for handling the warehouse – as was the case with this project. The creation of new warehouses did not result in the need to employ new warehouse workers.

- Better workflow in the warehouse and improved safety – this is mainly due to license plate scanning, vehicle weighing and Nazca connection to the monitoring and alarm system, as well as comprehensive management of the car park operation.

- Control over the entire process and possibility of anticipation of potential hazards.

- Last but not least, relative simplicity of configuration of the platform, which – thanks to being based on popular construction automation norms and an open structure – allows for including a number of warehouse management systems in it.

This is not the only realization for this contractor, see what else we have done for him. READ MORE