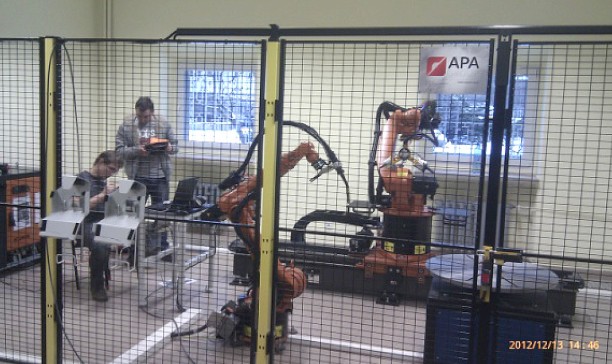

One 7-axis KUKA (KR 16) robot is provided with a double pneumatic SMC gripper and it picks elements (elements of the working part of a pavement combined machine) from a table and applies them to the cutting head of the cutting element. The second KUKA KR 6 arc robot is provided with a burner of a welding system made by FRONIUS, including an anti-collision module.

The robot simulates welding of an element applied to the head by the KR 16 robot. The entire process is supervised by a SIEMENS S7-1200 controller installed in an additional control cabinet, equipped with a monochromatic HMI 5.7” panel.

Concept

- 3D and 2D design of the entire robotic cell

- KUKA robot installation

- AXELENT fencing installation

- Working table installation

- Pneumatic gripper installation and connection

- FRONIUS welding unit and anti-collision module installation and connection

- Execution of the pneumatic installation, including compressor startup

- Control cabinet pre-fabrication

- PLC controller programming

- Programming of two KUKA robots KRC4 KR6 arc, KR16

- Visualization creation

- Program implementation

Project components

- Siemens S7-1214C central unit

- Simatic HMI Panel KTP600PN 5.7’MONO operator panel

- KUKA KRC4 KR6 arc, KR16 robots

- SMC pneumatics (actuators, electrovalves)

- FRONIUS welding unit

- Fencing (AXELENT X-GUARD) with an EUCHNER safety lock

- STANLEY compressor

- SEW MOVITRAC inventers