One of the Silesian leading service providers in the area of transport and logistics contacted APA with an order regarding energy optimization. That was almost two years ago, and today we can proudly recount how the initially set goal was attained.

Our approach

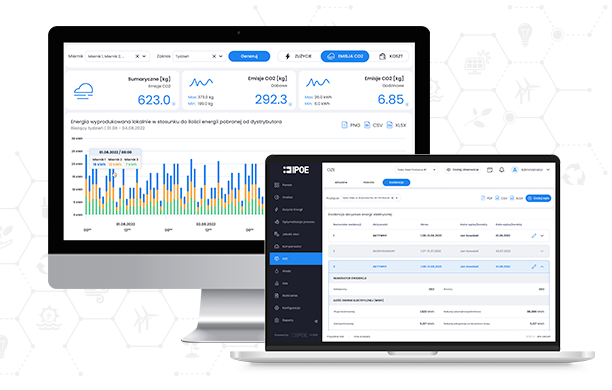

We build a comprehensive solution in close cooperation with the customer, by targeting their needs and expanding the system. We started by evaluating three production halls in terms of the quality and quantity of energy consumed by the facilities. This enabled the client to track current and archived energy consumption, quality and any anomalies or resource utilization that occurred, such as contracted capacity. Subsequently, we integrated the platform with three photovoltaic installations and provided a tool for maintaining electronic excise records. By using the IPOE platform, we can proactively compensate for reactive power and eliminate the penalties related to it.

What difficulties did we have to face?

One of the most challenging aspects for us was that the client's needs did not boil down to the "here and now", but stretched into the future.

Looking ahead, the assumption is the implementation of a digital utility management solution and, at a later stage, the need to integrate energy infrastructure (photovoltaic installations).

The need for environmental reporting for customers was also brought forward.

We have dealt with all these expectations with great success, and our implementation addresses not only the present state, but also can be flexibly modified.

What does the customer benefit from boosting energy efficiency with IPOE?

One hugely relevant aspect for the customer is environmental responsibility and the issue of CO2 emissions. The IPOE allows us to track the carbon footprint, or CO2 emissions in this case, resulting from the use of electricity.

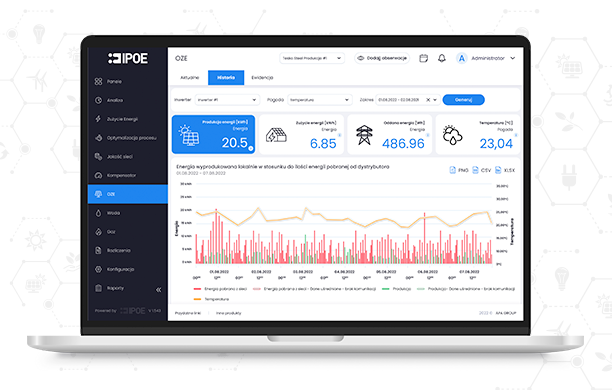

Given the importance of this aspect, the client decided to have a PV installed, which we then integrated into IPOE, while providing a tool for electronic excise records. By integrating the FV installation along with IPOE's existing measurements, the client gained comprehensive insight into the amount of energy consumed or produced, and, most importantly, what part of its production uses green energy that does not emit CO2 into the atmosphere.

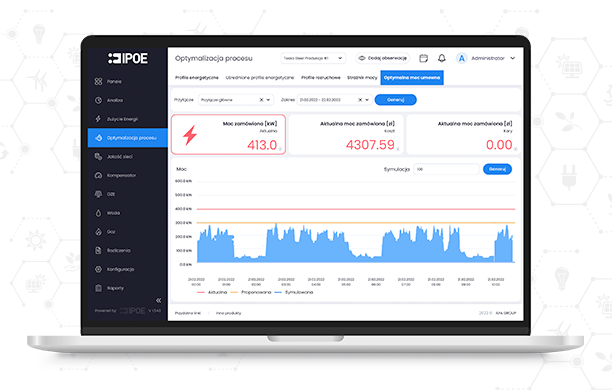

An equally important aspect for the customer is the proper compensation of reactive power, which in excess is associated with additional penalty charges on the electricity bill. As a result of leveraging IPOE, we have selected the appropriate equipment to offset any penalties and overruns. In addition, we continuously track the relevant parameters, so that the customer immediately learns about any undesirable occurrence.

Finally, the client gets weekly managerial reports from APA to guide production management and business development decisions.

In summary, we have obtained full control over:

● the energy generated and consumed, its intake and release to the grid;

● environmental aspects and carbon footprint tracking of manufactured products.

Technologies applied

- Network analyzers to control the quantity and quality of energy consumed in three production halls.

- Data concentrator: Router with GSM modem.

- Data processing: IoT Azure cloud.

- Integration with inverters of the photovoltaic system.

- Reactive power compensation.

- APA's IPOE system:

- real-time monitoring of quantitative and qualitative energy parameters,

- a transparent and easy-to-read interface,

- the ability to export data to Excel,

- optimization algorithms,

- a power quality and anomaly alert system,

- reports on energy quality and consumption,

- a system of electronic excise records.

This is not the only realization for this contractor, see what else we have done for him. READ MORE